Tacho integration on our platform is moving fast. Despite the summer holidays, we still managed to find time to test one of the most popular, compact, yet incredibly smart trackers from Ruptela.

- Custom CAN

- What makes Custom CAN so special?

- Custom CAN configuration

- Live tachograph data and D8 interface

- Device Profile Switching (DPS)

- How to configure DPS

Characteristics breakdown

In short, HCV5 Lite is a high-quality, reliable, and stable tracker with support for 4G, CAN, and Custom CAN - its flexible configuration is aimed at technically skilled specialists. Well suited for monitoring cargo and special vehicles, using RS232/RS485, but with some limitations.

The tracker has a switchable interface: RS232, RS485, or K-Line. That is, only one of these three interfaces can be selected for operation, unlike the full HCV5 model, which has two RS232 ports, one RS485, and K-Line simultaneously.

The device supports complex external devices via a switchable RS interface in transparent channel mode:

RFID readers: for driver identification or access control (e.g., by card).

Displays or terminals: for showing information to the driver, receiving commands, and statuses.

Fuel level sensors (with digital output): if working via MODBUS/RS.

Weighing systems and code readers: especially used in logistics, garbage trucks, and special vehicles. Most weighing systems (e.g., from manufacturers like VEI, MOBA, Dinamica Generale, Pfreundt) use RS232 or RS485 to connect with external systems – whether a terminal, tracker, or operator panel.

Industrial controllers: hydraulics, lifting mechanisms, press, pump, crane boom that use RS232 or RS485 as the main communication interface.

“SOS” buttons, alarm panels, and other accessories.

HCV5 Lite also supports reading data from the CAN bus, tachograph, and digital inputs. Though this requires careful and precise configuration, especially when working with Custom CAN, there are some helpful automation tools for K-Line, FMS, and OBD2. I'd note that it's an ideal choice for tasks where CAN telematics is important, but extended peripheral support is not required.

Additional features worth mentioning:

Support for 1-Wire (temperature and humidity sensors, iButton, card readers)

Bluetooth 5.0 (beacons, sensors)

Firmware Over-the-Air (FOTA) updates via Ruptela's Device Management Platform

Support for geofences and schedules

Compact form factor, convenient for hidden installation

Custom CAN

Before we dive into the most interesting part, let’s quickly explain what the CAN bus is. It’s a network that allows various electronic control units (ECUs) – like the engine, transmission, brakes, and even the infotainment system – to communicate with each other. Data such as vehicle speed, fuel level, engine RPM, door status, and much more passes through this bus. Each unit doesn’t “address” messages to a specific receiver but simply broadcasts them. All others listen to the bus and process only the messages relevant to them.

Nowadays, many telematics trackers can read some standard CAN bus data, such as FMS, J1708, and J1939. They provide basic parameters. But HCV5 Lite takes this to a whole new level with its customizable Custom CAN feature. This means the tracker can be precisely configured to extract specific, often unique data directly from the vehicle’s CAN bus.

What makes Custom CAN so special?

Imagine you have a specialized fleet – maybe refrigerated trucks, concrete mixers, or even agricultural machinery. These vehicles often have unique sensors and systems that generate data crucial for their operation. A standard GPS tracker can tell you where the truck is and how fast it’s moving, but it won’t tell you the temperature inside the refrigeration unit, the rotation speed of the mixer drum, or the status of specific attachments.

Unlike regular trucks, where engine and chassis parameters can be obtained via the FMS protocol, specialized equipment – like concrete mixers, garbage trucks, cranes, or watering machines – usually transmit their superstructure data via non-standard CAN protocols unique to each manufacturer. Such data can’t be accessed through standard FMS and requires Custom CAN, which allows you to “catch” and decode the necessary IDs and bytes on the CAN bus. Examples of these parameters include:

Concrete mixer: drum rotation speed, rotation direction, loading/unloading mode, water temperature, engine RPM of the superstructure

Garbage truck: opening/closing of the rear door, compactor activity, cycle completion, hydraulic errors, pressure overload

Crane / multilift: outrigger position, boom activation, cylinder pressure, outreach/angle limits, stabilizer errors

Watering machine: pump activation, nozzle rotation, water level, supply temperature, selected mode

Container truck / multilift: lock status, container fixation, loading cycle completion, lifting speed, container position error

Thus, effective monitoring of specialized equipment requires detailed CAN traffic analysis and precise Custom CAN setup to extract the right parameters from the non-standard CAN messages of a particular equipment model.

Custom CAN configuration

Custom CAN configuration is a complex and meticulous process that requires specific engineering knowledge and extensive experience, understanding the vehicle’s structure, CAN protocol operation principles, message formats, and exact CAN IDs for the required parameters. It’s also crucial to understand how everything is physically connected and how the equipment operates at the bus level. We’re talking about full custom tuning.

Even if the manufacturer (for example, a concrete mixer) provides the protocol and parameter descriptions, it doesn’t guarantee the correct and quality use of the data. To set up Custom CAN properly, you need to go through the entire parameter identification process.

All configuration is carried out in Advanced Mode, which demands a high level of attention and expertise, as incorrect values or accidental changes may cause improper device performance and loss of functionality. For example:

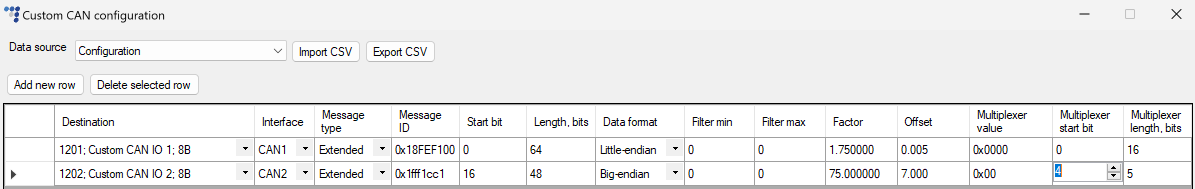

- If you have a complete and precise ECU parameter specification – not just CAN IDs, but also exact calculation formulas, multipliers, masks, bit positions, and byte order – then this is the easiest case, where you “just” need to fill in the parameter fields in the configurator. That’s not even counting debugging and troubleshooting, which will inevitably come up :)

- The configurator supports importing parameters from a .csv file – if one is available. However, even when a technical description from the manufacturer exists, it’s rarely provided as a ready-to-use CSV. Most of the time, parameters have to be entered manually, which brings us back to the previous point.

- The device also supports loading encrypted configurations. This feature is useful if the manufacturer provides all necessary parameters but doesn’t want to reveal protocol details, or if an integrator has developed a custom configuration under agreement.

- It’s also important to keep in mind that the ECU parameter specification can come in many different formats. Usually, the manufacturer of the unit describes only a set of parameters and calculation coefficients: under what conditions, in what format, and how exactly to interpret the values. But all of this ultimately needs to be converted into the structure that the Ruptela configurator understands. The main point is that every manufacturer has their own approach to documentation, and it rarely matches how parameters are set in Custom CAN. Ruptela requires strict compliance with the configurator’s structure – specifying IDs, masks, offsets, multipliers, and data types. So, the chance that a manufacturer will provide a ready-made table or instructions like “just enter it this way into Ruptela” is practically zero.

- In some cases, parameters are obtained through CAN sniffing – manual analysis of traffic and matching bytes to actual values. This is the most hardcore way to identify the necessary parameters and can only be used in the most extreme and advanced cases, requiring the highest level of knowledge and experience. This happens when there’s some special equipment without documentation, or the manufacturer refuses to provide it for some reason. With the tracker correctly connected to the vehicle’s proper CAN bus (and there may be several), you can read all the data sent by different ECUs. This is done using the USB CAN Logger utility and special equipment – a branded USB-CAN adapter or similar gear that allows reading “raw” CAN messages directly from the vehicle’s bus and displaying them in real-time for further analysis and Custom CAN configuration.

In particularly tough cases, where you need to go even deeper, universal CAN adapters and sniffers like SavvyCAN or Wireshark with SocketCAN are used. There, you have to manually capture not just packets but the bitstream with arbitration, stuffed bits, and errors, and try to figure out where exactly in this chaos the needed parameters live.

Conclusion: Custom CAN configuration is, to put it mildly, a very complex path to setting up the tracker to get the required parameters. But with the right experience, knowledge, and equipment, you can pull practically any data the vehicle transmits. It’s like working with a Swiss Army knife in the world of telematics – a versatile and powerful tool, but it demands precise understanding of how and where to use it.

The photo of the parameter configuration is presented as a demonstration and serves only to show the possibilities and variety of configuration parameters.

Sample Illustration of USB CAN Logger.

Live tachograph data and D8 interface

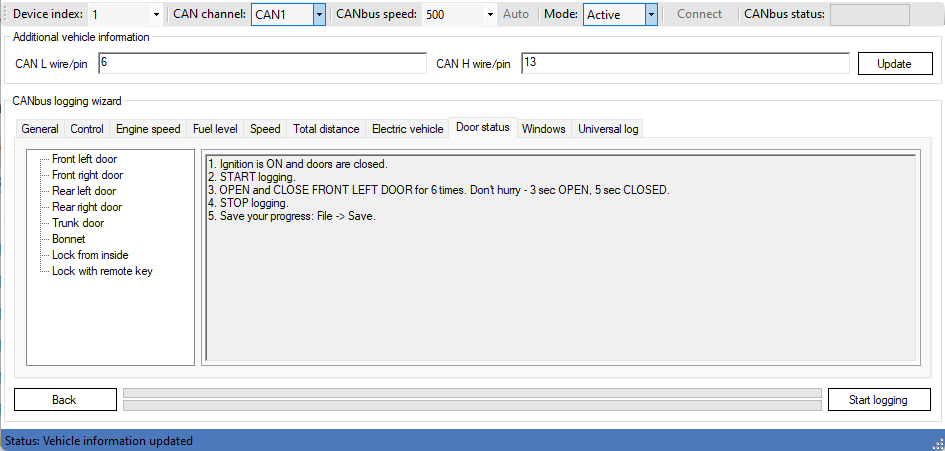

HCV5 Lite offers a key feature – live tachograph data – which lets you get real-time info like driver status, card activity, tachograph errors, current time, and more. This works through both CAN and K-Line interfaces, fully supported in HCV5 Lite on hardware and software levels.

The D8 interface provides a standard data stream from the tachograph, and the pre-configured Tacho Read mode in the configurator enables easy setup for data reception. Reading is possible via both CAN bus and K-Line (pin 7, brown wire), which is crucial since some tachographs operate on only one of these channels. Some tachographs require authorization or may block the D8 port programmatically — this depends on the model and country.

Data you can get:

Driver status (driving, rest, work, readiness)

Active card (driver 1/2)

UTC time, errors, VIN, card numbers (if allowed)

Basic tachograph events and alarms

Driving time, shifts, etc. (limited)

Which tachographs support D8?

This info was gathered from available sources, so please double-check the tachograph’s official specs before actual use, as models may vary by version and region.

VDO DTCO 1381 (including versions 4.0 / 4.1)

Stoneridge SE5000 with firmware versions above 7.0 (both 1st and 2nd gen)

EFAS-4 or newer

Device Profile Switching (DPS)

A cool feature that’s available but barely known – and even less used. And it’s not just about the HCV5-Lite. The tracker can switch its profile based on specific conditions, adapting its settings to the situation. This is a slick feature that lets you use the tracker way more flexibly, save on data traffic, and extend battery life when needed. Here are some real-life examples:

Protecting equipment during off-hours (security mode)

Scenario: At night, equipment parked outside is often tampered with, or fuel gets stolen.

Solution:- From 10 pm to 6 am, the security profile kicks in.

- Inputs like door, hood, and fuel tank sensors get activated.

- If triggered → siren turns on (via output), and an alert is sent.

Roaming/working abroad

Scenario: Equipment crosses a country border, and GPRS costs spike.

Solution:- When the country changes by MCC → the “No Data Transmission” profile switches on.

- Data transmission turns off, and everything logs to memory.

- Once back in the home country, logs auto-upload.

Working in a warehouse / inside a geofence

Scenario: High accuracy and control are needed inside a warehouse or production area.

Solution:- Entering a geofence triggers a profile with frequent GPS updates (e.g., every 5 seconds).

- Inputs controlling locks, gates, or equipment get activated.

Automatic switching based on equipment status

Scenario: The equipment only runs when the engine is on.

Solution:- When the onboard voltage is above 13V → active profile runs.

- If the voltage drops below 12V → switch to power-saving mode (GPRS off, minimal polling).

How to configure DPS

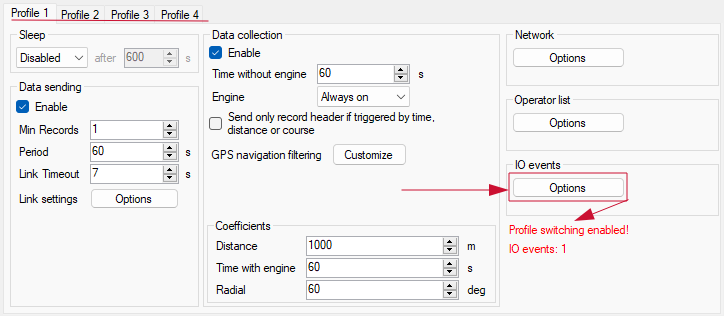

This kind of behavior can only be set up through Advanced Mode. At the bottom of the configurator, you can create and save up to 4 different profiles. Each profile lets you tweak data sending intervals, message polling frequency, data collection coefficients, and basically everything that directly impacts data traffic, battery life, and track quality.

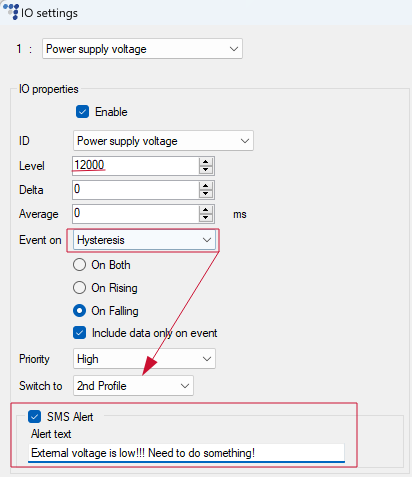

Next, you need to go to the IO Events tab, where the configuration of parameters sent by the tracker usually happens. Select the desired parameter – for example, Power Supply Voltage. Then specify the value at which the profile switch will trigger, in this case, when the voltage drops below 12 volts, and indicate which profile to switch to. You can also set up sending an SMS alert if needed! For more detailed info on configuration, check out the official manufacturer’s site in the setioparam section via the provided link.

Closing words

The Ruptela HCV5 Lite is a compact yet powerful telematics tracker, perfectly suited for complex cases in logistics, special machinery, and municipal services. It supports reading data from the CAN bus (including Custom CAN), provides access to live tachograph data via CAN and K-Line, and can flexibly respond to events by switching profiles based on conditions – delivering a high level of control, automation, and adaptability. Despite being a simplified version, the Lite model keeps the core features of the full series and offers maximum possibilities to those who know how to make the most of it.