Modern IoT asset tracking demands more than simple signals – every byte matters. When hardware manufacturers start exploring what platforms can do with their data, they gain more than just integration – they gain insight. Once they understand how easily data can be processed, enriched, and reused after it’s received, they can start designing smarter products and offering new digital capabilities to their clients. Instead of merely connecting BLE sensors to a backend, they begin to shape the value that comes after the data arrives.

ELA Innovation, a French-based developer of industrial Bluetooth sensors and beacons, embraced this mindset when linking their latest BLE trackers to the flespi platform, unlocking new possibilities for real-world applications.

From cost-cutting to cold-chain control

Back in the 1950s, McDonald’s faced a familiar business dilemma – how to cut costs without compromising product quality. Refrigeration was expensive, so the company took a shortcut: it replaced traditional ice cream with powdered milkshakes that required no cold storage.

In modern logistics, however, there’s no such shortcut. The temperature of goods in transit can’t be “faked” or ignored – it must be tracked, documented, and maintained across the entire cold chain. That’s where BLE-based temperature sensors step in.

While large enterprises might rely on sophisticated, all-in-one monitoring platforms, such systems can be overkill – too expensive and complex for small and mid-sized operators. BLE devices, on the other hand, offer a lean, flexible alternative: they provide reliable temperature visibility, long battery life, and simple deployment at a fraction of the cost.

This approach democratizes IoT monitoring – making advanced telemetry accessible even to smaller logistics companies, local distributors, and cold-chain service providers who couldn’t justify traditional industrial systems before.

BLE ID: tracking made simple

Beyond temperature, BLE technology shines in identification and proximity tracking. BLE ID tags – tiny, battery-powered transmitters – continuously broadcast their unique identifiers to nearby gateways or smartphones. They don’t need GPS modules or SIM cards, yet they can deliver surprisingly rich visibility into where assets, tools, or people are at any given time.

What used to require complex RFID infrastructures or heavy IoT gateways can now be handled with a pocket-sized tag and a mobile app. That simplicity lowers barriers for smaller companies – warehouses, construction fleets, or rental services – helping them obtain the same operational awareness that enterprise-scale systems have long enjoyed.

Modern BLE protocols and smart gateway logic reduce traditional Bluetooth limitations, enhancing accuracy and reliability even in dense industrial environments. As part of a unified data chain, these signals can be converted into structured, real-time intelligence that fuels automation, analytics, and smarter decision-making across industries.

Connecting the links

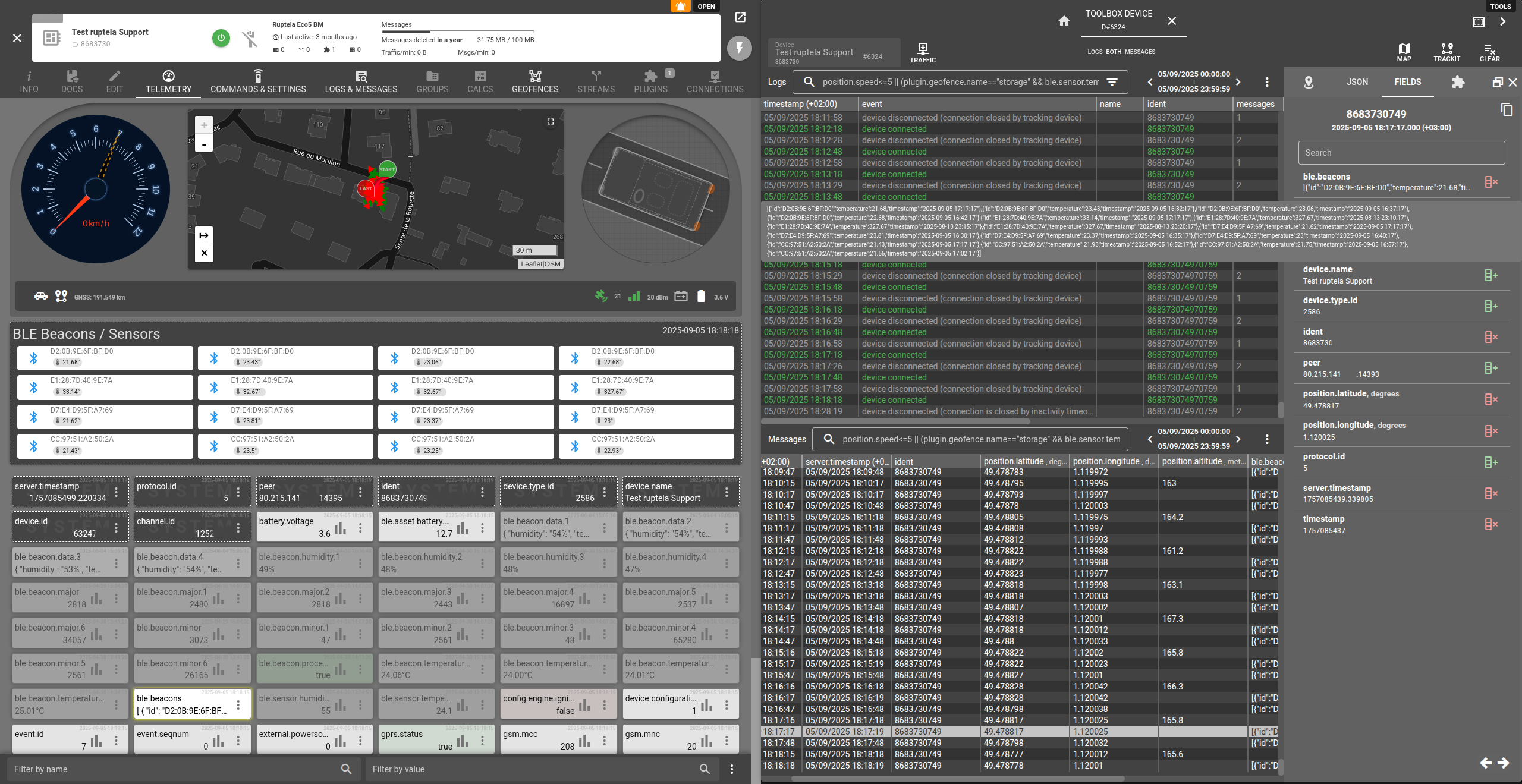

At the Telematics & Connected Mobility conference held this September in Vilnius, ELA Innovation demonstrated that their sensors are natively compatible with flespi without any custom development. They also confirmed that any BLE‑compatible tracker can serve as a bridge between their sensors and our platform.

Using the iBeacon format, they showcased that the Ruptela Eco5 tracker can manage multiple sensors in parallel, which is crucial for use cases such as asset tracking or temperature monitoring in insulated containers. Wandrille Lesueur, Sales Director at ELA Innovations, noted:

"flespi platform, which integrates a multitude of data formats (including ELA) and virtually all market trackers, simplified the process. We used the iBeacon format because it is the most basic format that all BLE-compatible trackers integrate first – the vast majority of BLE beacons on the market use that format. The challenge was encapsulating measurement data in a frame format that was not initially designed for this purpose."

Yes, it's not suitable for data that changes over time (each iBeacon tag theoretically has a fixed frame). The team applied their original Bluetooth Advanced Features, which allow for in-depth customization of an iBeacon's payload. Remarkably, there is no theoretical limit to the number of sensors a single tracker can handle, as long as the hardware side is tough.

Integration of ELA sensors was significantly accelerated thanks to the AI Assistant (hey, codi!). In particular, he generated code to reconstruct useful data from raw frames, even without in-house development expertise. ELA Innovation is now preparing the next round of sensor integration, defining iBeacon profiles that interface directly with flespi. This frame format enables more technical cooperation with GPS trackers and removes constraints such as whitelisting and strict limits on the number of manageable sensors.

Well, sounds like the beginning of a long journey – wishing all the best of luck! Probably, you are ready for this road too?