Grocery stores are highly dynamic businesses with a lot of moving parts, tons of things to optimize, and thin profit margins. Ensuring in-time deliveries to avoid out of stock situations and minimizing the idle time for fleets, roll cages and reusable conveyances used can improve operational efficiency and lead to savings as well as higher customer satisfaction.

Borderless Hub — a company headquartered in Singapore, a fully owned subsidiary of Ascent Solution — embarked on a project aimed at optimizing the fresh produce delivery and the use of third-party-owned roll cages by one of the major local grocery chains. Having vast experience providing Global M2M Data SIMs, designing IoT hardware devices, and crafting IoT software solutions, Borderless Hub was perfectly qualified for the project.

Let’s now look at what the developed solution has under the hood.

IoT-enabled fleet management solution

The example here is a chain of 100+ grocery stores across Singapore. The fresh produce is restocked every day and is delivered to the stores in roll cages owned by a third-party company. Once a roll cage or reusable conveyance is unloaded, it sits waiting to be collected and returned to the warehouse.

What Borderless Hub came up with is a comprehensive custom IoT solution providing the tracking of delivery trucks, monitoring temperature and humidity for the goods being delivered, ensuring cargo safety, notifying about loading/unloading events, optimizing the turnaround of the roll cages, tracking of the chain of custody, and more.

On the hardware side

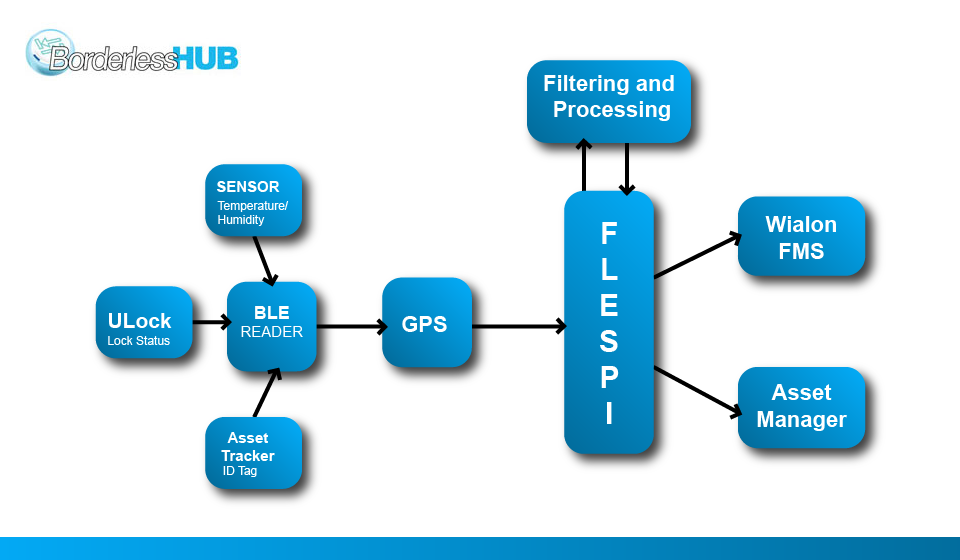

The solution relies on a handful of hardware devices to cover all the needs:

GPS tracker — used to track the truck location in real-time, as well as collect the data from the BLE devices.

BLE sensors — placed in different corners of the truck to monitor the temperature and humidity; needed to ensure freshness of delivered produce.

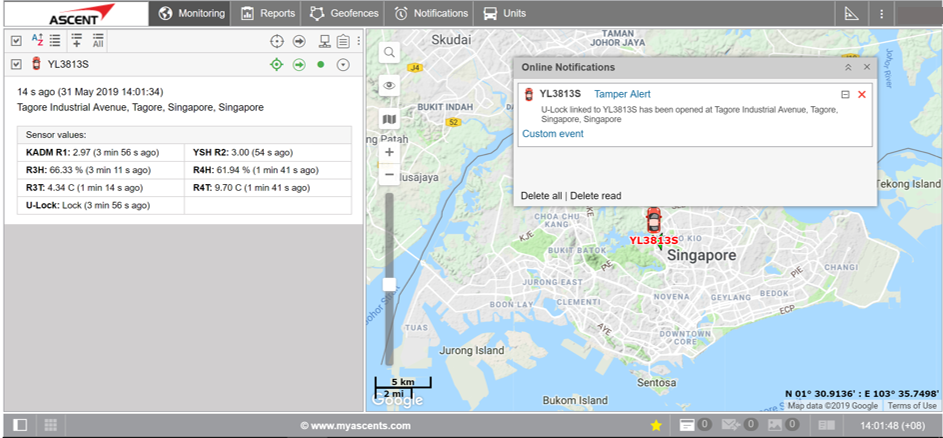

BLE lock — installed on the roll cage; allows detecting unauthorized openings outside the designated geofence around the stores.

BLE asset tag — attached to the roll cage and reusable conveyances; enables monitoring the state of the entire roll cage (when it’s loaded, unloaded, and in transit).

BLE reader — mounted at the back of the truck; used to register when the roll cages are loaded/unloaded from the truck and remember their location based on the geofence they were unloaded in.

On the software side

In a word, the data from all the above-listed hardware flows into flespi and then the “right” data is forwarded to the proper platforms for analysis, decision-making, and event-generation.

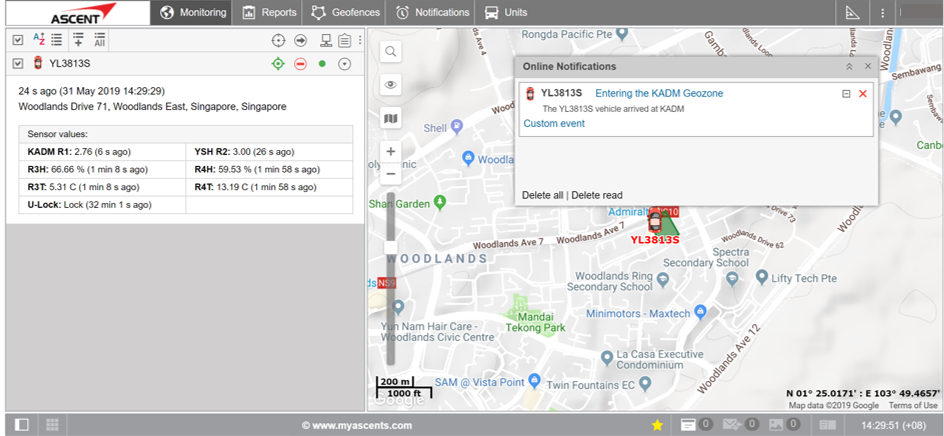

Most of the data end up in Wialon — location data is used to show the delivery trucks on the map; the lock data is used to notify of unlocking events outside any of the store geofences; temperature and humidity sensors reading are used to notify about critical deviations from the recommended values.

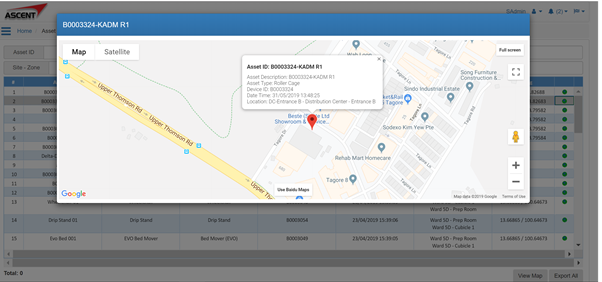

The data about the roll cages and reusable conveyances location go to the asset management system to inform the company owning the cages where they are and whether they are unloaded so that it can plan the best route for the pickup.

Outcomes

- Deployment of such a solution would assist the customer in achieving better security, visibility, and control over delivery operations.

- This data can contribute to better decision making together with identifying inefficient processes in order to optimize operations.

- Real-time tracking and sensor data will allow coordinators to have a real-time view of what is happening on the ground and be able to re-route trucks based on traffic conditions, assess security breaches in real-time and identify when the cold chain is about to be broken.

- This together with the ability to know the last known location of assets such as roll cages can decrease re-purchasing activities of assumed “lost” assets.

Overall, this digital solution based on IoT technology will be able to provide decision-makers with real data to have a holistic view of the operations outside of the distribution center.

Flespi uses

Borderless Hub has been gradually immersing in the world of flespi and is already using quite an extensive range of its versatile tools and capabilities. Some of them directly contributed to the end product, while others just simplified the development process and saved time to the team.

Let us briefly highlight the key flespi contributions to the given project.

“Flespi is great for sensor-based networks.”

Device management & configuration

The guys from Borderless Hub built a nice dashboard to monitor device states based on telemetry functionality and the universal device configurator. It allows informing whether the device is reporting or dead, what the firmware version is, and a lot of other parameters. The UI is customized in such a way as to restrict users to certain actions — commands, reset, reboot but prevent from messing around with critical parameters.

Using the subaccounts functionality of the flespi platform the solution enables users to log in with their subaccount credentials and see their fleet status only.

Data streaming

As mentioned above, one stream of data goes to the Wialon fleet management platform for fresh produce monitoring.

Another stream forwards the pre-filtered data to the asset tracking system for roll cages monitoring.

Troubleshooting

Borderless Hub team uses the proxy channel to see if there is a problem with raw data from the device. If yes, they can redirect traffic to the HW manufacturer without dropping the connection with the software platform.

Toolbox utility helps view the logs and messages in a convenient format with intuitive color schemes, easy filtering, real-time and history modes.

Instant events processing

With flespi, it’s easy to implement any data pre-processing, filtering or transformation before it goes any further. The steps are as follows:

Create an MQTT channel in flespi and subscribe to device events

Use the script with the desired functionality to perform any data filtering and transformation required.

Publish the processed events back into flespi for further forwarding elsewhere.

Example: Borderless Hub uses BLE tags in areas with no GPS coverage (e.g. in tunnels). Once the BLE location data gets into flespi, the script replaces it with the corresponding GPS value and publishes the modified message back to the flespi channel. Then the rightly formatted message goes to Wialon.

***

The IoT solution by Borderless Hub uses a blend of technologies and hardware devices to address the peculiarities of the retail industry and provide a seamless experience to operators, managers, and decision-makers in dealing with the delivery fleet, maintaining the high quality of produce, and minimizing the risk of improper handling.